Build, repair, and enhance metal parts with precision, speed, and confidence.

What is Laser Directed Energy Deposition (LDED)?

Laser Directed Energy Deposition (LDED) is a metal additive manufacturing technology that repairs, enhances, and builds metal parts without replacing the whole thing.

Using a high-powered laser, LDED melts either metal wire or powder, depositing it precisely where needed, layer by layer. The result?

You don’t have to scrap worn shafts or cracked housings, LDED can restore them to original spec quickly, without the lead time or cost of starting over.

Laser Wire LDED

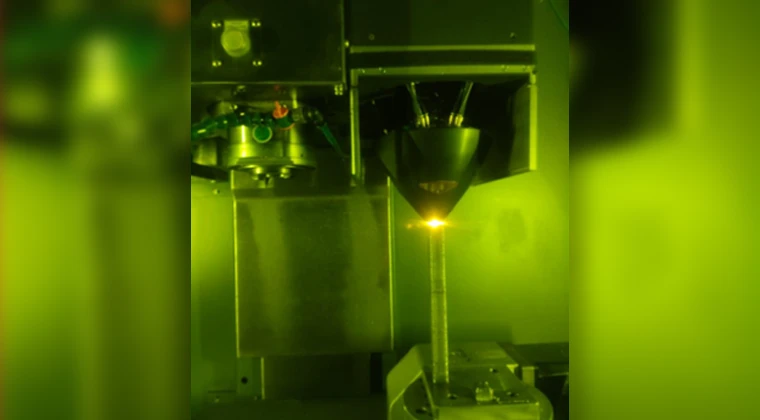

Laser Wire Directed Energy Deposition (LDED) is a powerful additive manufacturing process that lets you build or repair metal parts by feeding a continuous wire into a melt pool created by a high-powered laser.

The laser melts the surface of the part (or previous layer), while the wire fuses into it forming strong, clean metallurgical bonds. An inert shielding gas like argon protects the process from oxidation, keeping the material quality consistent and defect-free.

The system follows a digital design, precisely depositing material exactly where it’s needed, with the freedom to create complex shapes, overhangs, or multi-material sections.

Why Choose Laser Wire DED?

Trusted by manufacturers across sectors where precision, uptime, and traceability matter most.

With m2nxt, You don’t just monitor: You understand, Optimized, and excel.